Introduction

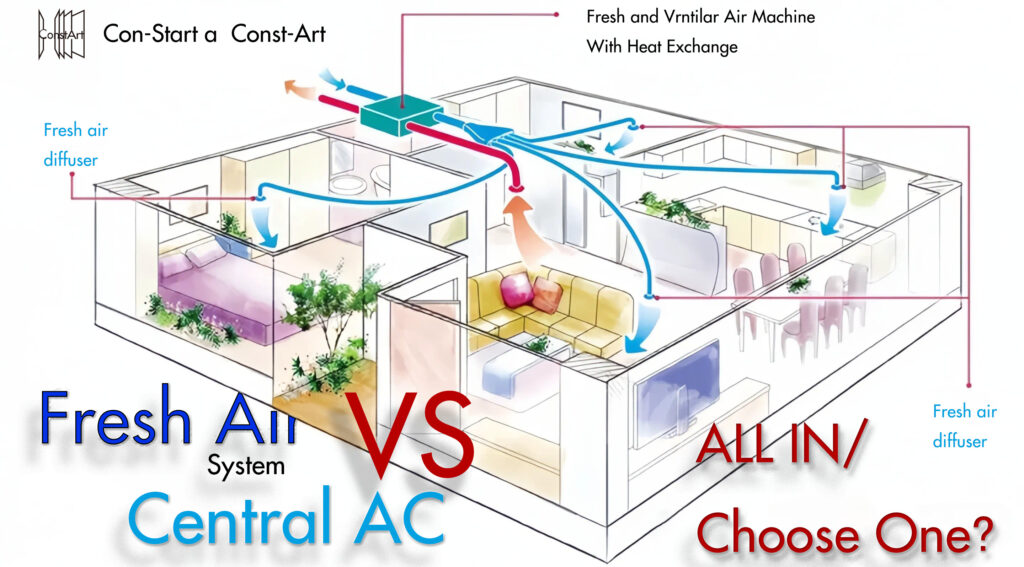

In modern building design, HVAC systems (Heating, Ventilation, and Air Conditioning) play a crucial role. The design of HVAC ducts and air outlets directly impacts indoor comfort, air quality, and energy efficiency. A well-designed system can effectively regulate indoor temperature, ensure good air circulation, and avoid air pollution and energy waste. This article will explore the basic principles, methods, and considerations in the design of HVAC ducts and air outlets in buildings.

1. Principles of HVAC Duct Design

HVAC ducts, acting as the “blood vessels” of the system, are responsible for transporting hot and cold air to maintain the required indoor temperature and humidity. The primary goals of duct design are to ensure smooth airflow, minimize energy loss, reduce noise, and guarantee long-term system stability.

1.1 Selection of Duct Materials

The choice of duct material directly influences the system’s efficiency and durability. Common materials include galvanized steel, aluminum, stainless steel, and composite materials. Galvanized steel has good corrosion resistance and mechanical strength, making it suitable for most applications; aluminum is lightweight and easy to process, ideal for buildings with strict weight requirements; stainless steel is used in environments requiring high corrosion resistance, such as damp basements or industrial buildings with corrosive gases.

1.2 Duct Size and Shape Design

The size of the duct directly affects airflow speed and pressure loss. Typically, duct size should be determined through fluid dynamics calculations to ensure airflow speed and pressure loss are within reasonable limits. Air velocity is generally recommended to be between 6-12 m/s; excessively high speeds can lead to increased noise and decreased system efficiency.

The shape of the duct is also crucial. Rectangular ducts, which occupy less space, are suitable for installation in ceilings or narrow corridors; round ducts, with lower wind resistance and pressure loss, are better for long-distance air transport.

1.3 Duct Layout and Support Design

The layout of ducts should follow the principle of the shortest path to reduce pressure loss and energy consumption. It is also important to avoid sharp bends and excessive branching to minimize turbulence and noise.

Support design should consider the weight of the ducts and thermal expansion effects to ensure the ducts do not deform or shift during long-term use. The spacing of supports is typically determined based on the size and material of the ducts, generally maintained between 1.5-3 meters.

2. Principles of Air Outlet Design

Air outlets are the points of interaction between the HVAC system and indoor spaces, and their design directly impacts the uniformity of indoor air distribution and comfort. Proper air outlet design can effectively avoid issues like uneven temperature distribution, airflow dead zones, and noise problems.

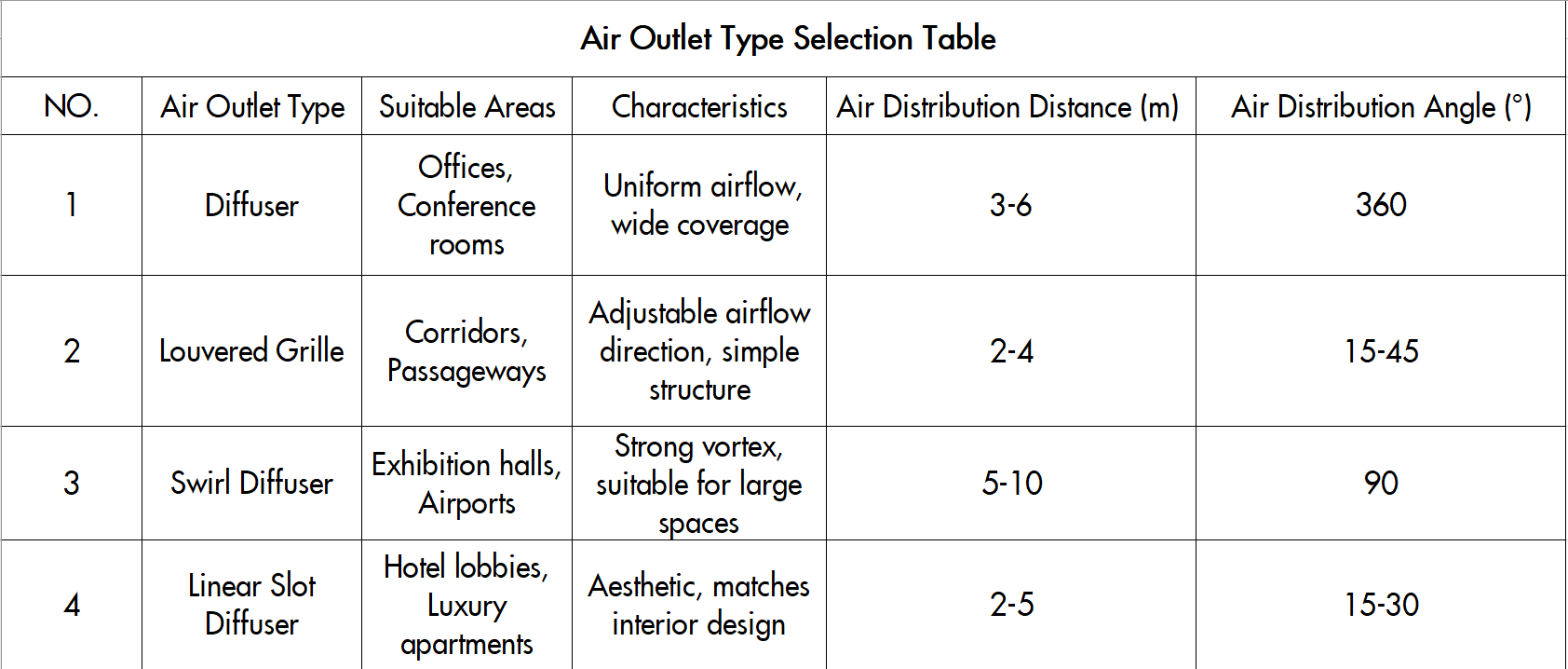

2.1 Selection of Air Outlet Types

Common air outlet types include diffusers, louvered grilles, swirl diffusers, and linear slot diffusers. Diffusers are suitable for large areas requiring uniform air distribution, often used in offices and conference rooms; louvered grilles can adjust the direction of airflow, suitable for corridors and passageways; swirl diffusers create strong vortexes, ideal for large spaces or high ceilings like exhibition halls and airport terminals; linear slot diffusers are primarily used in aesthetically demanding areas, such as hotel lobbies and luxury apartments.

2.2 Placement of Air Outlets

Air outlet placement should be based on indoor airflow patterns and usage requirements. Supply air outlets are usually placed at the top of the room or high on the wall to utilize the natural convection of rising warm air for more even air distribution. Return air outlets should be placed lower to promptly capture waste air and cold air from the room.

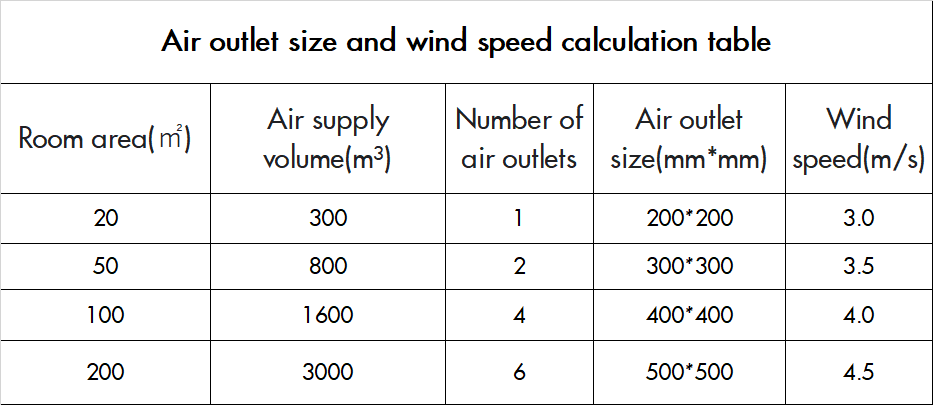

2.3 Determining the Number and Size of Air Outlets

The number and size of air outlets should be based on the room’s size, function, and required air supply volume. The size of the air outlet can typically be determined by calculating the airflow speed and air supply volume. To avoid discomfort caused by excessively high local airflow speeds, the outlet velocity is usually controlled between 2-4 m/s.

2.4 Design of Air Outlet and Duct Connections

The connection design between air outlets and ducts should minimize resistance and noise. Air volume control dampers or silencers are usually installed at the connection point to precisely control the air supply and reduce noise. The sealing performance of the connection is also crucial to prevent air leakage and heat loss.

3. Considerations in Design

In addition to the basic principles mentioned above, the following points should be considered during the actual design process:

3.1 Balancing Aesthetics and Functionality

In projects with high interior design requirements, the design of air outlets should balance aesthetics and functionality. Designers can choose appropriate air outlet types and materials based on the interior decoration style, or even customize specific shapes and colors to achieve harmony with the overall design.

3.2 Noise Control Considerations

Noise generated by the duct and air outlet system primarily comes from high airflow speeds, turbulence, and equipment vibration. To reduce noise, the design should aim to lower air speeds, reduce sharp bends, and select duct materials and air outlet types with good sound attenuation properties. Installing silencers between fans and air outlets is also a common noise reduction measure.

3.3 Adapting to Special Environmental Requirements

In special environments such as clean rooms, laboratories, and hospital operating rooms, the design of ducts and air outlets must meet higher air cleanliness and anti-pollution requirements. Designers should consider installing high-efficiency filters, keeping duct inner walls smooth and dust-free, and ensuring air outlets have good sealing performance to prevent external contaminants from entering.

3.4 Considering Energy Efficiency

Energy efficiency is a key objective in modern HVAC design. The design should consider ways to reduce pressure loss within ducts, select efficient air outlet types, and avoid unnecessary energy waste. Installing variable frequency fans and air volume control valves to adjust airflow based on actual demand is also an important measure to improve system energy efficiency.

4 Actual design case

4.1 Case of HVAC design in office buildings

Take an office building with an area of 1,000 square metres as an example, carry out the design of heating and ventilation pipes and air outlets. The building requires heating in winter and refrigeration in summer, and the indoor temperature is kept between 22-26°C and the relative humidity is 40%-60%.

4.1.1 Air duct design:

• Total air volume calculation:

• Office area: 700 m³/h

• Conference room: 1200 m³/h

• Corridor: 500 m³/h

• Total air volume: 2400 m³/h

• Air duct size:

Choose a circular air duct, the diameter of the main air duct is 400mm, and the diameter of the branch pipe is 200-300mm.

Stress loss:

• The total pressure loss of the main air duct is estimated to be 25Pa, and the pressure loss of the branch pipe is controlled between 10-15Pa.

4.1.2 Air outlet design:

• Air outlet type selection:

• Dispersers are used in the office area, cyclone air outlets are used in the conference room, and shutter air outlets are used in the corridor.

• Air outlet size and quantity:

• A 200 x 200mm disperser is installed in the office area every 20 square metres; Four pieces of 400 x 400mm cyclone vents are installed in the conference room; and two pieces of 300 x 300mm shutter vents are installed in the corridor.

• Noise control:

• The wind speed in the office area is controlled below 3m/s, and the noise level is below 35dB. The conference room adopts silence measures to ensure that the noise does not exceed 40dB.

Conclusion

In the design of building heating ducts and air outlets, the application of tables and data makes the design process more systematic and scientific. This not only improves the accuracy of the design, but also helps engineers make reasonable decisions in practice. Combined with specific engineering cases, through scientific calculations and table comparison, the performance of the HVAC system can be effectively improved to meet the comfort and energy-saving requirements of the internal environment of the building.

Some fo Related Products on ConstArt ,Click to detail: